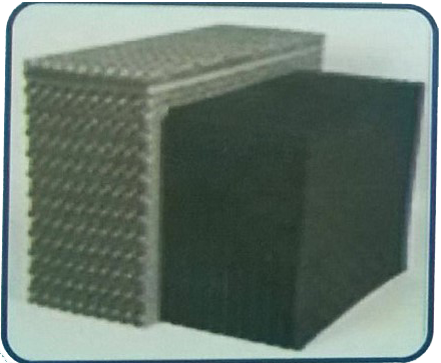

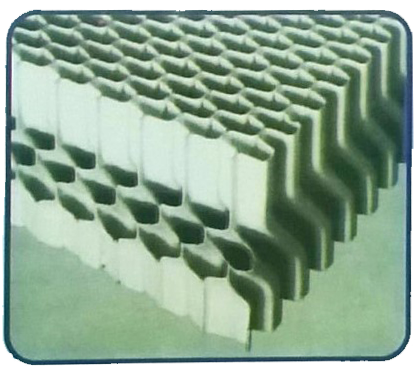

Wide Range of Capacity

Available in 20 diffrent models from one cell to twenty cells, both in Counter Flow & Cross Flow, "Anew Tower Tech" (ATT) has model for every application and capacity. If there is a special application, "ATT" will design a cooling tower that will fit your requirment. Contact with "ATT" head office or your local representative for alternative cooling tower solution.