Products & Services

Applications

What Is Cooling Tower?

Cooling tower is an equipment used to cool the water, which is required for industrial and AC & R purpose. Principal of cooling is based on evaporation. Cooling tower maximize the water surface area,this water surface area comes in contact with air, top layer of water surface gets evaporate leaving behind inner surfaces of water cool.

Types of Cooling Tower:

Based on operation, basic types of cooling tower are:

1) Mechanical draft cooling tower

In this cooling tower air draft is created by means of fan. There are two types of mechanical draft cooling tower.

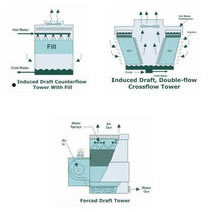

a) Induced Draft

In this tower air draft is induced through the cooling tower. Fan comes on top of cooling tower, which sucks the air through cooling tower. Again there are two types of induced draft of cooling tower.

i) Counter flow cooling tower

This tower is box type in which water flows down and air flows up causing counter current between air and water. These type of cooling tower are compact compare to cross flow cooling tower.

ii) Cross flow cooling tower

This tower comes in inclined shape in which water flows down and air flows in 90 degree to water, causing cross current between air and water.

Again based on type of material used for cooling tower construction, these towers are divided in Steel, RCC, Timber, FRP, Pultruted FRP etc.

b) Forced draft

In this tower air draft is created by forcing the air in to cooling tower by means of fan. In this tower fan is installed at side bottom of cooling tower.

2) Natural Draft Cooling Tower

In this cooling tower air draft is created naturally and there is no need of fan to create draft. Air draft is created because of venturi shape of tower and density difference of air at inlet and air at outlet. These towers are economical for large cooling water requirement, for example more that 40,000 CMH. For such large requirement these tower are advantageous because they needs less space, less maintenance, zero operational cost for fan power compare to induced draft. But capital cost of this tower is more compare to induced one.