Products & Services

Cooling Tower Components

We are engaged in providing Cooling Tower Components. These includes the following :

• PVC Film Fills

• Splash Fills

• Casing & Fan Deck

• PVC Drift Eliminators

• FRP Fan

• Cooling Tower Motor

• FRP Fan Cylinder

• Gear Reducer

• Drive Shaft

• Water Distribution Systems

Fills

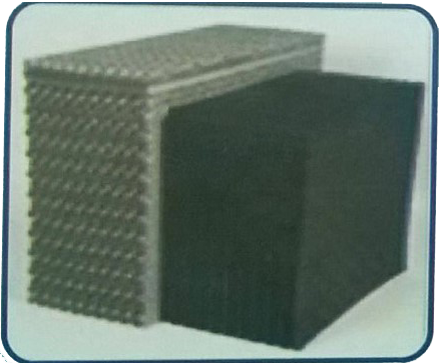

(a) PVC Film Fills

Film allow the water to form thin flowing sheets to expose as much water surface area as possible to the interacting airflow. Fills are double edge folded to provide additional strength erosion resistance at edges and longer life. These PVC fill shall resistant to rot, or biological attack and non-brittle. The PVC fills have excellent fire resistant qualities, with a flame spread rating as per ASTM-E84.

Higher temperature fills are available for water temperatures exceeding 55 ° c, consult your "Anew Tower Tech" representative for further details.

We use below type of PVC fills:

(i) Cross-Fluteed Film Fills: Cross fluted PVC film fills, which offers maximum

heat exchange surface area,

minimum pressure drop and higher

water-air mixing time in result increase cooling tower thermal efficiency.

Suitable for good water and industrial water quality,

(ii) vertical offset Fills: This fills has less fouling change, efficient and maximum

surface area.

(iii) vertical Fills: Good for dirty water, low fouling and low pressure drop.

(b) Splash Fills

Splash fills are good for dirty water application and offer low pressure drop. Below available splash fills are used for "Anew Tower Tech" cooling towers:

(i)Wooden Splash Bar: Chemically treated wooden bars sed for cross-flow cooling tower.

(ii) PVC "V" Bar: PVC "V" Bars makes small ts by splashing and shearing of

water drops which produce better heat transfer efficiency. used both for

cross-flow and counter flow cooling tower & suitable for turbid water application.

PVC V-Bar

(iii) Opti - Grid : Opti - Grid is a direct replacement of splash fill for use in cross-flow and counter flow towers where dirty water is concern. opti-grid utilizes a floating hanger design that allows the fill layers to float for excellent fit in slanted cross-flow designs. This design offers reduced pressure drop, improved splash surface, non fouling ability and maximum strength. Good for sea water and turbid water.

(iv) TURBosplashPAC: Due to innovative design, there is no risk for the fills getting chocked, less resistance to the passage of air allows energy saving. Suitable both cross-flow and counter-flow cooling tower and any type of water quality including sea water.

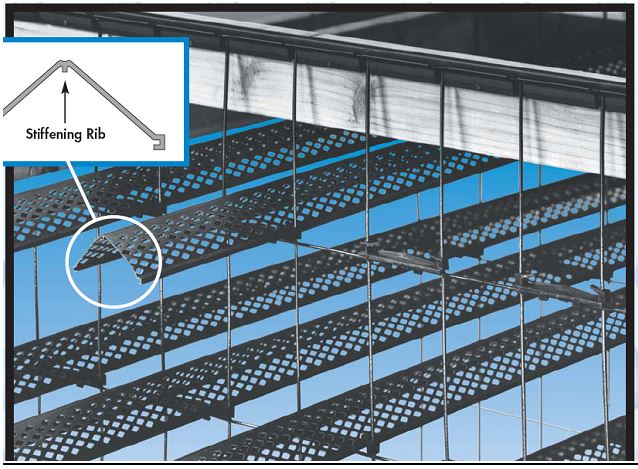

Casing And Fan Deck

The endwalls and sidewalls of the tower from air inlet elevation to the top of perimeter fan

deck shall be cased with corrugated non-corrosive FRP panels attached to columns. Panels

shall be lapped to shed water inward to the tower corner rolls shall be provided to cover casing

ends. Fan deck shall be FRP. For Rcc cooling tower casing & Fan Deck shall be of concrete.

The endwalls and sidewalls of the tower from air inlet elevation to the top of perimeter fan

deck shall be cased with corrugated non-corrosive FRP panels attached to columns. Panels

shall be lapped to shed water inward to the tower corner rolls shall be provided to cover casing

ends. Fan deck shall be FRP. For Rcc cooling tower casing & Fan Deck shall be of concrete.

PVC Drift Eliminators

"Drift" is the undesirable loss of liquid water to the environment via small droplets

that become entrained in the leaving air stream. These water droplets carry with

them chemicals and minerals thus impacting the surrounding environment

"Anew Tower Tech" use profile or cellular both type eliminator to ensure maximum

removal of water droplets from air stream to limit the drift rate up to 0.005% of

circulating water flow rate, with low rate, the "Anew tower Tech" cooling

tower saves valuable water and water treatment chemicals.

"Drift" is the undesirable loss of liquid water to the environment via small droplets

that become entrained in the leaving air stream. These water droplets carry with

them chemicals and minerals thus impacting the surrounding environment

"Anew Tower Tech" use profile or cellular both type eliminator to ensure maximum

removal of water droplets from air stream to limit the drift rate up to 0.005% of

circulating water flow rate, with low rate, the "Anew tower Tech" cooling

tower saves valuable water and water treatment chemicals.

The drift eliminators are constructed of polyvinyl chloride (PVC) plastic material

which corrosion of these vital components, They are

assembled in sections to facilitate easy removal for inspection and maintenance of the water distribution

system and top of the fill area.

FRP Fan

Our clients can avail from us a wide range of Energy Saver FRP Fan. These are used to transfer process waste heat to the atmosphere. Our fans are fabricated by using premium quality material like aluminum alloy & FRP and are balanced with variable pitch for high efficiency and low vibration. These energy saver cooling tower fans are extensively used in chemical plants, petrochemical plants and other industry applications.

Our clients can avail from us a wide range of Energy Saver FRP Fan. These are used to transfer process waste heat to the atmosphere. Our fans are fabricated by using premium quality material like aluminum alloy & FRP and are balanced with variable pitch for high efficiency and low vibration. These energy saver cooling tower fans are extensively used in chemical plants, petrochemical plants and other industry applications.

Pultruded FRP Cooling Tower

The Structural members are structural shapes pultruded FRP with a flame spread of 25 or less. The tower and all its components are designed to withstand a wind load of 1.44 kPa and a seismic load based upon UBC local design criteria. Fan decks and other work levels shall be designed for a uniform load of 2.88 kPa, or a concentrated live load of 272 kg.

The Structural members are structural shapes pultruded FRP with a flame spread of 25 or less. The tower and all its components are designed to withstand a wind load of 1.44 kPa and a seismic load based upon UBC local design criteria. Fan decks and other work levels shall be designed for a uniform load of 2.88 kPa, or a concentrated live load of 272 kg.

Columns and diagonal braces are 76mm x 76mm box section at a spacing no greater than 1829mm (6'-0) centers both longitudinally and transversely. Columns requiring anchorage will be anchored to the concrete cold water basin by heavy gauge series 304 stainless steel anchor clips. Perimeter columns are extended above the fan deck to act as posts for the deck perimeter hand railing.

A tension/compression system of diagonal braces shall stiffen the structure and transfer wind and seismic loads to the basin anchor points. Diagonals will be anchored to the cold water basin using heavy gauge series 304 stainless steel anchor clips. Horizontal members are open sections (typically channels and angles) and fill support members and fan deck supports are "C" channel sections.

FRP Fan Cylinder

The FRP fan Cylinder's is of various height with velocity recovery design for increased efficiency and are constructed of heavy ribbed fiberglass panels bolted together. A full radius inlet bell is provided for smooth airflow into the fan.

Fan and Motor

We offer widest range of fan and motor combinations to meet any type of cooling

needs.

We offer widest range of fan and motor combinations to meet any type of cooling

needs.

FRP Fans shall be heavy duty axial type dynamically balanced and highly aerodynamic.

They ensure minimal power consumption and trouble free operation. The fans

constructed of FRP blades, installed in a closely fitted cowl with venturi air inlet.

Fan Motors are totally enclosed fan-cooled, heavy duty, with 1.10 service factor and

suitable for cooling tower & outdoor application. "Anew Tower Tech" offers many

optional motors to meet your special needs.

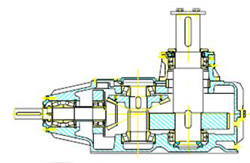

Gear Reducers

The right angle, double-reduction, spiral-bevel gear reducers is designed in accordance with AGMA

standards and CTI Bulletin STD-111. The speed reducers are sized with a minimum service factor

of 2.0 based on the motor nameplate horsepower, The bearings are lubricated by a positive

The fill, drain and vent lines are stainless steel and will extend outside of the fan

stacks and have a sight glass. The sight glass will

be marked to show normal lubricant level in the

reducer when it is not operating.

The right angle, double-reduction, spiral-bevel gear reducers is designed in accordance with AGMA

standards and CTI Bulletin STD-111. The speed reducers are sized with a minimum service factor

of 2.0 based on the motor nameplate horsepower, The bearings are lubricated by a positive

The fill, drain and vent lines are stainless steel and will extend outside of the fan

stacks and have a sight glass. The sight glass will

be marked to show normal lubricant level in the

reducer when it is not operating.

Drive Shaft

Each drive shall include a HDG / SS, single piece drive shaft connected by flexible, self-aligning couplings

to the motor and to the gear reducer. Each drive shaft and coupling set is sized for a minimum service

factor of 2.0 based on the motor nameplate rating as per CTI standard. The coupling hubs will be

keyed to the shafts, and the shafts assembly is dynamically balanced. Appropriate drive shafts arrestors

and coupling guards are supplied as per industrial requirements to protect equipments and operating personnel.

Each drive shall include a HDG / SS, single piece drive shaft connected by flexible, self-aligning couplings

to the motor and to the gear reducer. Each drive shaft and coupling set is sized for a minimum service

factor of 2.0 based on the motor nameplate rating as per CTI standard. The coupling hubs will be

keyed to the shafts, and the shafts assembly is dynamically balanced. Appropriate drive shafts arrestors

and coupling guards are supplied as per industrial requirements to protect equipments and operating personnel.

Water Distribution Systems

The spray header and branches shall be constructed of Heavy Duty, polyvinyl chloride pipe / Gl pipe for corrosion resistance and shall have a steel flange connection to attach the external piping. The piping shall be removable for cleaning purposes. The lateral pipes will be pvc material and connected to the main header with neoprene flexible couplings. The water shall be distributed over the fill by precision molded ABS / PP spray nozzles with large orifice openings to eliminate clogging.